- Home

-

Shop By Make

-

Shop By Brand

- 3D MAXpider

- Accel

- ACCESS Covers

- ACEI

- Aceomatic

- ACERA

- ACI

- Ackoja

- ACM

- ADARAC

- Addictive Desert Designs

- Adler

- Advanced Clutch

- Advics

- Advics-Sumi

- AE

- AEM Electronics

- AEM Induction

- Aeromotive Fuel System

- Aeroquip

- AFE Filters

- Aftermarket

- AGA Tools

- Agility Autoparts

- AGS Brake Lines

- Air Design

- Air Lift

- Air Products

- Airaid

- Airtex

- Aisan

- Aisin

- Ajusa

- Akebono

- AKG

- All Sales

- Allmakes PR2 PRO

- AlphaRex

- AMC

- AmeriBrakes

- American Car Craft

- AMK Germany

- AMO

- Amortex

- Amp Tires

- Anchor

- Anco

- Ansa

- ANZO

- AP

- AP Exhaust

- APA/URO Parts

- Arai Seisakusho

- ARC Lighting

- ARIES

- Arnott

- AST

- ATE Premium One

- Atlantic Automotive Eng.

- ATP

- ATS Diesel Performance

- Auburn Gear

- Auto Ventshade (AVS)

- Autocraft

- Autolite

- AutoMeter

- Autopart International X

- Autotecnica

- B&M

- Backrack

- Backroadz

- Baja Designs

- Bak Industries

- Balo

- Balo Coated

- Bando

- Banks

- Bargman

- BBK Performance

- BBR Automotive

- BD Diesel

- BedRug

- Bedslide

- Behr

- Bentley

- Beru

- Better Built

- Bilstein

- Black Horse Off Road

- Blau

- BMR Suspension

- Body Armor

- Body Armor 4x4

- Boge

- BOLT

- Borg Warner

- Borgeson

- Borla

- Bosal

- Bosch

- Bougicord

- Bowa

- Boysen

- Brandmotion

- Brazil

- Brembo

- Brembo Coated

- Bremi

- BrightSource

- Britpart

- Bruss

- Bull Ring USA

- Bully Dog

- Burgaflex

- Bushwacker

- Bussmann

- BWD Automotive

- BWD CQ

- BWI Group

- Cali Offroad

- Calorstat

- Calsonic

- Camko

- Canyon Engine

- Cardone

- CARQUEST

- Carr

- Carrand

- Carter

- Catco

- CEC Industries

- Centerforce

- Champion

- Chuo Spring

- CIPA

- ClearPlus Wipers

- Clevite

- Cloyes

- CMX

- Cofle

- Cognito Motorsports

- Cohline

- Cometic Gasket

- Continental

- ContiTech

- CoolXPert

- Cooper

- Corsa

- Corteco

- Covercraft

- Crosland

- Crown Automotive

- CRP

- Cruiser Accessories

- CSF

- CTEK Power Inc

- CTR

- CURT

- Curt Towing

- CVJ

- Dai-ichi

- Dansk - JP Group

- Dayco

- Daystar

- DEA Marmon Ride Control

- DEA Strut

- DEC

- DECKED

- Dee Zee

- Delphi

- Denso

- Denso Spark Plug

- Derale

- Design Engineering

- DiabloSport

- Diamond

- Dill Air Control

- DIRTY LIFE

- Dokuro

- DongA

- Doowon

- Dorman

- DPH

- Draw-Tite

- Driven Racing Oil

- Driveworks

- DS-One

- DU-HA

- Dura-Bond Bearing

- Duraliner

- DV8 Offroad

- Dynomax

- E3 Spark Plug

- Earl's Performance

- Eaton

- EBC Brakes

- Eberspaecher

- Edelmann

- Edge

- Egelhof

- EGR

- Eibach

- Elaplast

- Eldor

- Ellen

- Elring

- Elth

- Elwis

- EMPI

- Eneos

- Energy Suspension

- Equus

- European

- Eurospare

- Exedy

- Extang

- EZ

- Fab Fours

- Fabtech

- Facet

- Factor 55

- Factory Air

- FAE

- FAG

- Fastway Trailer

- Febi

- Fel-Pro

- FelPro

- FEQ

- Ferodo

- FIA

- Firestone Ride-Rite

- Flaming River

- Flowmaster

- FlowTech

- Fluidampr

- Ford Racing

- Forecast

- Four Seasons

- Fox Racing Shox

- Fram

- Frostbite

- FTE

- Fuel Injection Corp.

- Fuji

- Full

- Futaba

- G-FORCE Racing Gear

- G2 Axle and Gear

- Gates

- GB Remanufacturing

- GBR Fuel Injection

- Geba

- GEM TUBES

- Gemo

- Genius

- Genuine

- German

- Gibson

- Girling

- GKN Automotive

- Glyco

- GMB

- Go Rhino

- Goetze

- Goodyear

- Graf

- Grant

- Green Filter USA

- GT Styling

- H&R Special Springs LP

- Hanon

- Hawk

- Hayes

- Hays

- Hebmuller

- Hedman

- Heliolite

- Hella

- Hellwig

- Hengst

- Hepu

- Hi-lift Jack

- Hirschmann

- Hitachi

- HJS

- HKT

- Holley

- Hooker

- Hopkins Towing

- Hopkins Towing Solution

- HornBlasters

- Hotchkis Performance

- Huco

- Huf North America

- Hurst

- Husky Liners

- Husky Towing

- Hutchinson

- Hygrade

- Hypertech

- ICON Vehicle Dynamics

- Imperial

- INA

- Injen

- Innovative Creations

- Interfil

- Intermotor

- Intermotor CQ

- Ion Alloy

- Ion Trailer

- Iron Cross Automotive

- Ishino Stone

- Iwis

- Japanese

- JCC

- Je Pistons

- Jet Performance

- JKS Manufacturing

- Jurid

- K&N

- Kaco

- Kaehler Germany

- Karlyn

- Kat's

- Kayser

- KC HiLiTES

- Keukdong

- Kibi Gaskets

- King Engine Bearings

- Kiriu

- Kleinn Automotive

- Kobra

- Koito

- Kolb

- Kolbenschmidt

- Koni

- Kooks Custom Headers

- Koyo

- Koyo Cooling

- KP

- Kraze Wheels

- Kugel

- Kuzeh

- KYB

- KYB (old box)

- Kyosan

- Laengerer & Reich

- Lakewood

- Laso

- Leer

- Legendary Wheels

- Lemfoerder

- Lesjofors

- Litens

- Littelfuse

- Locksmart

- Lokar

- LOOP

- Luber-Finer

- Lucas

- LuK

- LUVERNE

- MacKay

- Magnaflow

- MagnaFlow Performance Exhaust

- Magneti Marelli

- Mahle

- Mallory

- Mando

- Manley

- Mann-Filter

- Maradyne

- Mark Automotive

- Marnal

- Maruichi

- MAS Industries

- Maval

- MaxTrac

- Maxzone

- Mayhem

- Mazzi

- MBRP Exhaust

- Mcleod

- Mecano Bundy

- Meistersatz

- Melling

- Melling Select Performance

- Metelli

- Metra Electronics

- Metrix

- Mevotech

- Meyle

- Mgp Caliper Cover

- Mickey Thompson

- Mikuni

- Mile Marker

- Mintex

- Mishimoto

- Mitsuba

- Mitsubishi

- Mitsubishi Electric

- Mitsuboshi

- MK Kashiyama

- Modine

- Monroe

- Monster Hooks

- Moog

- Mopar

- Motive Gear

- Motorad

- Motorad UltraStats

- Motul

- Mountain - Japan

- Mpulse

- Mr Gasket

- MSD

- MTC

- Musashi

- N-Fab

- Nabtesco Rocky

- Nachi

- Nakamura

- National

- National Bearing

- NDC

- NDK

- Needa Parts

- New Era

- Newco

- NGK

- Nichirin

- Niles

- Nippon Gasket

- Nippon Reinz

- Nishino

- Nissens

- Nissin

- Nitrous Express

- NOK

- Nolathane

- NOS

- Novo

- NPN

- NPR

- NPW

- NRF B.V.

- NSK

- NTC - TAMA

- NTK

- NTN

- NWB-Nippon Wiper Blade

- OCAP

- Odometer Gears

- Odyssey Batteries

- OE+

- OEM

- OEQ

- OEZ

- Ohno

- Old Man Emu

- Omega

- OPT

- Optima Batteries

- Oracle Lighting

- Original Equipment

- Orion

- Osaka

- OSK

- Osvat

- Overland Vehicle Systems

- Owens

- Pace Edwards

- Pacer

- Pacer Performance

- PaceSetter

- Pagid

- Painless Wiring

- Paramount Automotive

- Paraut

- Patriot Exhaust

- Pavement Ends

- Payen

- PBR

- Peak

- Penda

- Pentosin

- Pertronix

- Peterson

- Pex

- Philips

- PIAA

- Pierburg

- Pilenga

- Pilenga Coated

- Pimax

- Pioneer Cable

- Pop & Lock

- Posi-Lok

- Positive Plus

- Powercraft

- Powerflow

- Powermaster

- Powerstop

- Precision International

- Prenco

- Prestolite

- Prestone

- Pro Comp

- Pro Series

- Pro-Tec

- Professional Parts Sweden

- Proform

- Programa

- ProRYDE Suspension Systems

- Pudenz

- PUR

- Purflux

- Purolator

- Putco

- Pypes Performance exhaust

- Python

- Qa1

- QSTEN

- Qualiseal

- Quick Fuel Technology

- QuickSteer

- Quinton Hazell

- Race Sport

- Rain X

- Ram

- Rampage

- Rancho

- Ranco

- Raptor

- Raybestos

- ReadyLift

- Redline

- Redline Performance

- Reese

- Reference Number

- Rein

- Remflex Exhaust Gaskets

- Remy

- Retrax

- Reutter

- Rhino-Rack

- Richmond

- Ridetech

- Ridler

- Rightline Gear

- RIGID Industries

- Road Armor

- RoadSport

- Rocky

- Rough Country

- Roush Performance

- Royze

- Rubicon Express

- Rugged Off Road

- Rumble Exhaust

- Ruville

- Sachs

- Sachs Clutch Kit

- Saleri

- Sanden

- Sangsin

- Sankei 555

- Sankei Filters

- Sankei Switches

- Santech/ Omega Envir. Tech.

- SBS

- Scan-Tech

- Schaeffler

- Schrader

- Sealed Power

- Sebro

- Sebro Slotted

- Seibon Carbon

- Seiken

- Seiwa

- Seojin

- Shell

- SHW Performance Germany

- Siemens

- SIM

- Simpson Safety

- SKF

- Skunk2 Racing

- Skyjacker

- Smittybilt

- SNG

- Snow Performance

- South Bend Clutch

- Specialty Products

- Spectra Premium

- Spectre

- SpeedFx

- Spicer

- SPK

- Sportrack

- Sportz

- Spyder

- SST

- Stabilus

- Standard Ignition

- Standard Motor Products

- Stant

- Starla

- Steelcraft

- StopTech

- Stribel

- Strong Arm

- Superchips

- SuperSprings

- Superwinch

- Surco

- Surtrak Axle

- Suspa

- Swag

- SWF

- SWS Warning Systems

- T-Rex

- TAAP

- Taiho

- Taylor Cable

- TEC

- Technovance

- TechSmart

- Teito

- Terada

- Textar

- Textar ePad

- Tezuka

- Thermo-Tec

- THO

- Thule

- TI Automotive

- Timbren

- Timken

- Titan Fuel Tanks

- TKU

- TMC

- Tokico

- Tomco

- Top Quality

- TOR

- Touren

- TracRac

- TrailFX

- Trans-dapt

- Transit Auto

- Trico

- Trucktec

- Trucktec Automotive

- Truxedo

- TRW

- TSK

- TSU / Camellia

- Tuff Country

- Tuffy Security

- Turbonetics

- TYC

- Uchiyama

- UFI Filtration

- ULO

- UnderCover

- Uni-Bond Lighting

- Unity

- USA Industries

- UWS

- Vaico

- VAIP - Vision Lighting

- Valeo

- Vandervell Bearings

- Vandervell Valves

- VDO

- Vemo

- Vertically Driven Products

- Vibrant Performance

- Victor Reinz

- Vista-Pro

- VNE Automotive

- Volant

- WABCO

- Wagner Brakes

- Wagner Lighting

- Wahler

- WAI

- Walker Exhaust

- Walker Products

- Warn

- WBR

- WBR Coated

- Wearever

- WEATHER GUARD

- WeatherTech

- Wehrle

- Weiand

- Weigh Safe

- Weld Racing

- Wells

- Westin

- Whiteline

- Winhere

- Wix

- Wrightwood Racing

- WSO

- XtraClear

- Yamada

- YEC Japan

- Yukon Gear

- Zexel

- ZF

- Zimmermann

- Zimmermann Coated

- Zimmermann Coated X-Drilled

- Zimmermann Formula Z

- Zimmermann X-Drilled

- ZKW

- Top Models

- Blog

- Account

- Accessories and Fluids

- Air and Fuel Delivery

- Belts and Cooling

- Body

- Brake

- Driveline and Axles

- Electrical, Charging and Starting

- Electrical, Lighting and Body

- Emission Control

- Engine

- Exhaust

- HVAC

- Ignition

- Steering

- Suspension

- Tire and Wheel

- Tools and Equipment

- Transfer Case

- Transmission

- Wiper and Washer

1995 EBC Brakes Parts

EBC Brakes Parts in Canada

Canada EBC Brakes Parts

Here you will find the parts that we carry by EBC Brakes.

For many years, we have serviced our Canadian customers in delivering the parts in Canada. Since we only carry top quality brands, it is no surprise that we carry a selection of parts by EBC Brakes. A top manufacturer, EBC Brakes is well known for their quality and durability. Backed by a full warranty, you can be assured in your purchase of auto parts by EBC Brakes in Canada.

Not to be confused with all those other companies who only state to be Canadian but actually operate out of the States; we are your 100% Canadian based auto parts source. All parts, including EBC Brakes that we sell through our website are stocked in Canada. No exceptions. To our customers this means no duties or any kind of border broker fees.

Some parts by EBC Brakes in Canada have been known to be difficult to obtain. We do our best to stock a large selection of parts by EBC Brakes in our Canadian warehouses. If we don't have a specific EBC Brakes part that you are looking for, contact us and we will do our best to obtain it.

For many years we have served thousands of Canadian customers delivering EBC Brakes parts in Canada. We have received admiration from customers throughout. We have become the Canadian trusted source for purchasing Canada EBC Brakes parts. With offices in Toronto and warehouses in most Provinces in Canada including Ontario and British Columbia, you can be assured that you are purchasing your EBC Brakes parts from a trusted Canadian source.

Filters

Filters

Loading...

Showing 1 - 3 of 3 products

Image

SKU

Product

Rating

Price

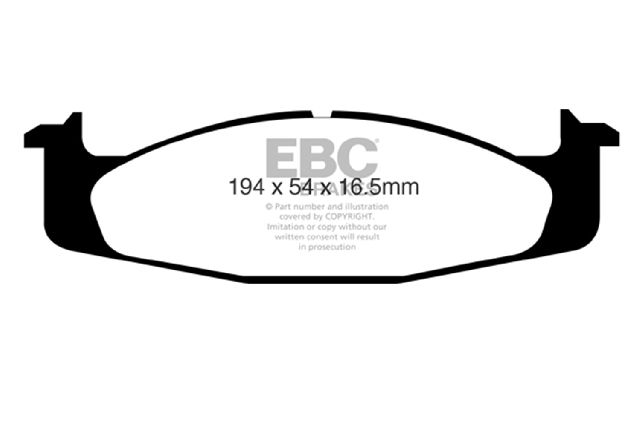

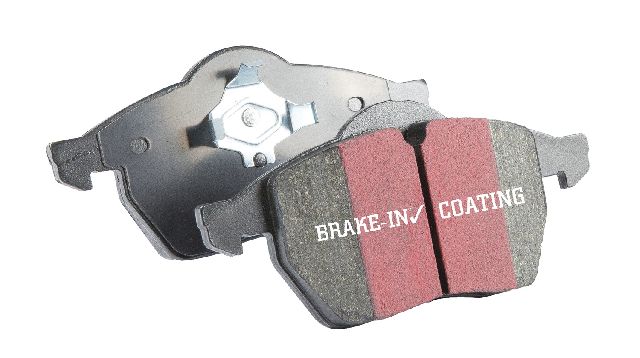

- FMSI Pad No. D632; Vented; 297mm Dia.; 133mm Height; 26mm Thick; 86.3mm Center Hole Dia.; Pad Dimensions: 195 x 70 x 17mm

- Ultimax OEM Replacement Brake Pads; FMSI Pad No. D632; Vented; 297mm Dia.; 133mm Height; 26mm Thick; 86.3mm Center Hole Dia.; Pad Dimensions: 195 x 70 x 17mm;

- Ultimax OEM Replacement Brake Pads

- Product Attributes:

- WARNING CA Proposition 65: No

- Caliper Type: Oem

-

Features:

- Premium OE Replacement Pad

- Ideal For Daily Driver Use

- High Friction European Spec Friction

- Shimmed Slotted And Chamfered

- OE Hardware

- If you simply need a quality OEM replacement pad, look no further than Ultimax. Made in the UK Bristol EBC Brakes manufacturing plant Ultimax is a beautifully engineered brake compound that lasts well, produces minimal dust and is the perfect choice for the urban or daily driver. Why spend more if all you need is a quality replacement pad.The Ultimax pad does include a small percentage of steel fibre to achieve its price point, far less content than our competition where steel fibre content can attain 50 volume and this optimum fibre blend is what makes Ultimax both popular and unique amongst brake blends .Once bedded in Ultimax will inspire confidence in any car light truck or SUV no matter how you drive.Its universal heat range abilities and low rotor wear are additional benefits of the Ultimax pad range which is the EBC worldwide number one selling brake with numbers of sets sold running into tens of millions over the recent years. Unlike many of our performance grades Ultimax has remain unchanged as a pad compound for ten years now, a true testament to its success and customer acceptance. Why change a winning formula.Black coded in the EBC range EBC Ultimax is a fully ECE R 90 approved brake pad range and at its lower price point, less than HALF the price of original parts yet TOTALLY EQUIVALENT by nature of its R 90 brake safety approval, Ultimax offers great value for money and first class driving safety.When replacing brakes of any kind please remember how important brake safety is to your own well being and either have a professional mechanic install your new brakes or if you are a qualified mechanic use the EBC installation DVD as a guide in support of your vehicle owner's manual. These installation guide DVD tasters can be viewed here and the full DVD purchased from online vendors.

- They are sold as a set and only quantity 1 is required for both wheels

Additional Fitment Information:

| Vehicle | Block | CC | Position | Engine | CID |

|---|---|---|---|---|---|

| 1995 - Ford F-150 | V | 5753 | Front | 8 Cyl 5.8L | 351 |

1 In Stock

$109.47 CAD

$131.36 CAD

| Brand | EBC Brakes |

|---|---|

| Part # | E35UD632 |

| Condition | New |

| Warehouse | B |

- For FMSI Pad No. D422; Vented; 4 Bolt Holes; 252mm Dia.; 49.2mm Height; 20mm Thick; 68mm Center Hole Dia.

- 3GD Series Sport Slotted Rotors; Front; For FMSI Pad No. D422; Vented; 4 Bolt Holes; 252mm Dia.; 49.2mm Height; 20mm Thick; 68mm Center Hole Dia.;

- 3GD Series Sport Slotted Rotors

- Product Attributes:

- WARNING CA Proposition 65: No

- Style: Oe

-

Features:

- Wide Slots Helps Brakes Run Cooler

- Reduces Brake Fade Under Load And At Speed

- Removes Dirt Dust And Debris From Braking Zone

- Great For Truck/SUV/Towing/For Sedan Use

- Anodized For Protection/Gold For Imports

- Anodized For Protection/Black For Domestics

- All EBC rotors are made from OE spec grey cast iron, exactly as used on new car production and as many as we have tools for are BRITISH MADE wholly in our own UK foundry. Currently EVERY SINGLE ROTOR sold in Europe and the UK is BRITISH MADE and a majority of the designs specific to the USA are also BRITISH made.The British foundry is constantly expanding its in house tooled range but EBC like every brake manufacturer ....does need occasionally to buy some rotors in from approved sources to complete ranges in overseas markets. None of our competitors will ever tell you where their rotors come from and we at EBC are as disappointed as the rest of the world that cost pressure means there is not ONE foundry left in the USA to supply such parts, other brake brands when asked about origin will just sidestep the question. When we do buy rotors in, they are specified, sampled, tested for element analysis, grain structure, tensile strength, hardness and optimum ductility and tested 100 piece by piece to be perfect for runout on this in house machine.

- Sold Each. Purchase quantity 1 for 1 wheel

Additional Fitment Information:

| Vehicle | Position | Sub Model |

|---|---|---|

| 1995 - Nissan 240SX | Front | Base |

1 In Stock

$260.38 CAD

$312.46 CAD

| Brand | EBC Brakes |

|---|---|

| Part # | E35GD504 |

| Condition | New |

| Warehouse | B |

- For FMSI Pad No. D272; Solid; 5 Bolt Holes; 258mm Dia.; 46mm Height; 9mm Thick; 68mm Center Hole Dia.

- 3GD Series Sport Slotted Rotors; Rear; For FMSI Pad No. D272; Solid; 5 Bolt Holes; 258mm Dia.; 46mm Height; 9mm Thick; 68mm Center Hole Dia.;

- 3GD Series Sport Slotted Rotors

- Product Attributes:

- WARNING CA Proposition 65: No

- Style: Oe

-

Features:

- Wide Slots Helps Brakes Run Cooler

- Reduces Brake Fade Under Load And At Speed

- Removes Dirt Dust And Debris From Braking Zone

- Great For Truck/SUV/Towing/For Sedan Use

- Anodized For Protection/Gold For Imports

- Anodized For Protection/Black For Domestics

- All EBC rotors are made from OE spec grey cast iron, exactly as used on new car production and as many as we have tools for are BRITISH MADE wholly in our own UK foundry. Currently EVERY SINGLE ROTOR sold in Europe and the UK is BRITISH MADE and a majority of the designs specific to the USA are also BRITISH made.The British foundry is constantly expanding its in house tooled range but EBC like every brake manufacturer ....does need occasionally to buy some rotors in from approved sources to complete ranges in overseas markets. None of our competitors will ever tell you where their rotors come from and we at EBC are as disappointed as the rest of the world that cost pressure means there is not ONE foundry left in the USA to supply such parts, other brake brands when asked about origin will just sidestep the question. When we do buy rotors in, they are specified, sampled, tested for element analysis, grain structure, tensile strength, hardness and optimum ductility and tested 100 piece by piece to be perfect for runout on this in house machine.

- Sold Each. Purchase quantity 1 for 1 wheel

Additional Fitment Information:

| Vehicle | Position | Sub Model |

|---|---|---|

| 1995 - Nissan 240SX | Rear | SE |

1 In Stock

$146.54 CAD

$175.85 CAD

| Brand | EBC Brakes |

|---|---|

| Part # | E35GD7141 |

| Condition | New |

| Warehouse | B |

Showing 1 - 3 of 3 products

Loading...

Cart

Verifying Inventory....

Done

Confirming Price....

Done

Adding to Cart....

Done